In the industrial machinery sector, safety and efficiency aren’t just priorities—they’re business imperatives. Whether you’re managing a fabrication floor, overseeing plant operations, or handling equipment maintenance, stairs are often overlooked as a source of risk. Stair treads might seem like a small detail, but they play a major role in preventing slips, protecting equipment operators, and ensuring OSHA compliance.

By learning how to install stair treads without professional help, manufacturing and engineering teams can reduce downtime, cut costs, and maintain greater control over their facility’s safety measures.

What Are Stair Treads and Why Do They Matter in Industrial Environments?

Stair treads are the horizontal surfaces that workers step on while using stairs. In an industrial setting, stairs are often made of steel or concrete—both durable but slippery, especially when exposed to oil, grease, or metal shavings.

Properly installed stair treads provide:

Slip resistance in high-traffic zones.

Noise reduction, making communication on the floor safer.

Extended lifespan of stairs, protecting against wear from heavy boots or equipment transport.

Regulatory compliance, helping facilities meet OSHA and ANSI standards.

Can Industrial Teams Really Install Stair Treads Without a Contractor?

Absolutely. Manufacturing and engineering professionals already possess the technical mindset, tools, and hands-on experience needed to tackle such a project. Unlike structural retrofits, stair tread installation is straightforward and requires minimal disruption.

Example: At one Midwest machining facility, the maintenance team installed rubber anti-slip stair treads across two stairwells in less than a day. Not only did it eliminate the risk of oil-related slips, but it also saved the company over $5,000 compared to bringing in outside contractors.

Step-by-Step: How to Install Stair Treads Without Professional Help

1. Assess Your Stairs

Inspect for damage, rust, or uneven surfaces.

Ensure the base material (metal, wood, or concrete) is structurally sound.

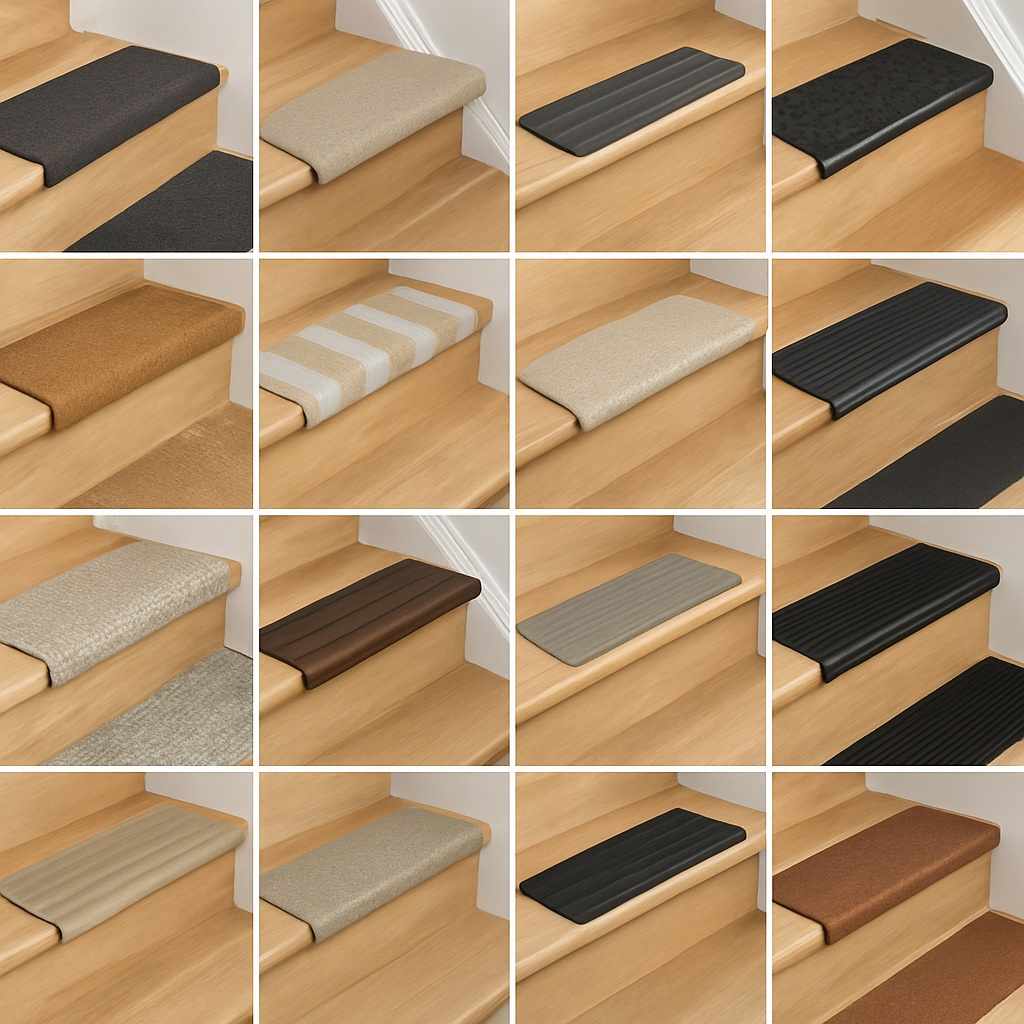

2. Choose the Right Tread Material

Rubber: Ideal for high-slip environments.

Vinyl: Cost-effective and easy to clean.

Metal grating with non-slip coating: Perfect for heavy-duty operations.

Carpet-backed rubber: Noise-reducing in administrative areas near the floor.

3. Gather Tools and Supplies

Most installations require only:

Industrial adhesive or pre-applied tape backing

Measuring tape

Utility knife or cutting tool

Safety gloves and eye protection

4. Prepare the Surface

Clean thoroughly—remove dust, oil, and debris.

For metal stairs, use a wire brush or grinder to clear rust.

For concrete, ensure it’s dry before applying adhesive.

5. Install the Treads

Measure and cut treads to fit each stair.

Apply adhesive evenly or peel backing.

Press firmly and ensure alignment.

For added security in heavy-use areas, fasten with screws or rivets.

6. Test and Inspect

Walk the stairs multiple times with different footwear.

Ensure no edges are lifting or peeling.

Record installation in your maintenance log for compliance tracking.

What Are the Key Benefits for Industrial Facilities?

Cost Savings

By installing in-house, companies can save thousands in labor costs and reduce downtime waiting for contractors.

Safety Improvements

Slip-resistant stair treads can reduce workplace accidents, lowering incident reports and insurance claims.

Flexibility

Maintenance teams can adapt installation schedules around production, avoiding costly disruptions.

Team Empowerment

Empowering staff to handle facility improvements fosters ownership and pride in the work environment.

How Does This Apply to the Industrial Machinery Sector Specifically?

In environments where machinery produces vibrations, oils, or cutting fluids, stairs often become hazard zones. Installing stair treads without professional help means:

Quicker hazard mitigation: No waiting weeks for vendor scheduling.

Tailored solutions: Maintenance engineers understand facility workflows better than outsiders.

Scalable application: Easy to replicate across multiple plants, warehouses, or production lines.

For example, in an automotive parts manufacturing plant, engineers noticed frequent near-misses on stairs leading to a mezzanine housing CNC machines. Within hours, the internal team installed rubberized treads designed to grip even when wet. The result: zero slip incidents over the next year.

Final Thoughts: Why Take the DIY Approach?

For manufacturing and engineering professionals, stair tread installation is more than a safety project—it’s a chance to combine technical expertise with practical problem-solving. By taking ownership of the process, facilities can boost safety, cut costs, and demonstrate proactive leadership in workplace risk management.

FAQ: Installing Stair Treads in Industrial Facilities

Q1: Are there OSHA requirements for stair treads in industrial plants?

Yes. OSHA 1910.25 outlines requirements for stairways, including slip-resistant surfaces. Installing stair treads is a simple way to meet these standards.

Q2: What is the best tread material for oily environments?

Rubber or abrasive-coated metal treads provide the best slip resistance in areas prone to oil or coolant spills.

Q3: How long do stair treads last in heavy industrial use?

With proper installation and maintenance, rubber or vinyl treads typically last 3–5 years in high-traffic zones, while metal-coated treads can last over a decade.

Q4: Do I need to shut down operations to install stair treads?

Not necessarily. Installation is quick and can often be scheduled during shift changes or slow periods.

Q5: How do I maintain stair treads after installation?

Regular cleaning with industrial degreasers, plus visual inspections during routine maintenance checks, ensures longevity and performance.

Q6: Can stair treads reduce worker fatigue?

Yes. Rubber treads provide cushioning that reduces strain on knees and backs—especially valuable for workers moving between machinery stations multiple times per shift.

Q7: Are adhesives strong enough for heavy-duty stairs?

Yes, when surfaces are properly prepped. For added security in high-load areas, screws or rivets can supplement adhesives.

Q8: Is this approach scalable across multiple facilities?

Definitely. Standardized tread materials and in-house installation protocols can be applied plant-wide or across different sites.

Q9: How much can a facility save by self-installing treads?

Savings range from 40–60% compared to outsourcing, depending on the number of staircases and materials chosen.

Q10: What common mistakes should be avoided?

Failing to clean surfaces before installation.

Choosing the wrong material for the environment.

Skipping alignment checks, leading to uneven placement.

Write a comment ...